Unmatched Precision and Quality at Sancliff, Inc.

Discover the finest custom shaped wire drawing dies at Sancliff, Inc. in Worcester, Massachusetts. Since 1948, we have led the industry in producing high-quality custom shaped drawing dies, employing the latest Wire EDM, CAD, CAM, and inspection technologies to ensure exceptional accuracy and performance.

Quality You Can Rely On

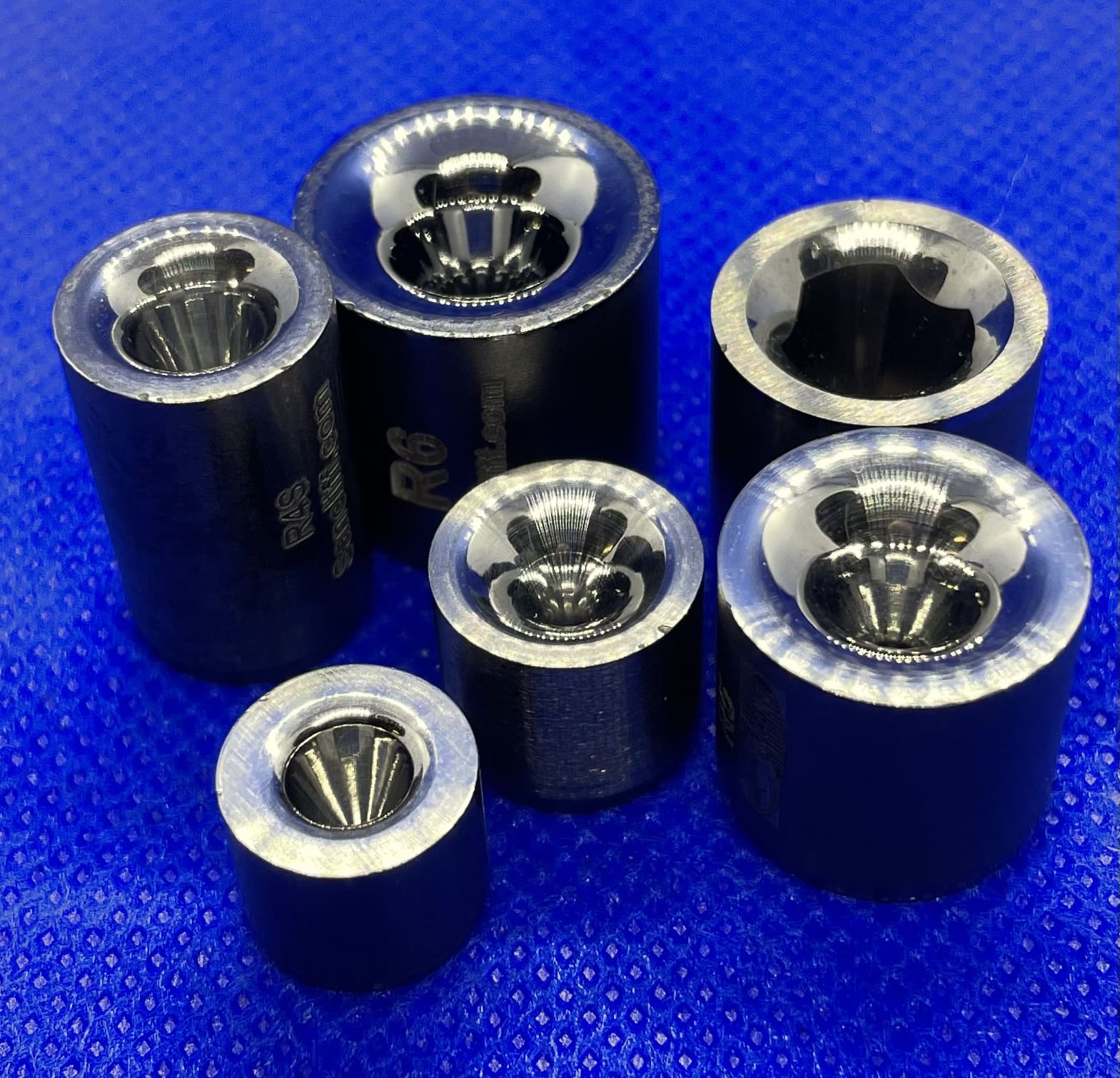

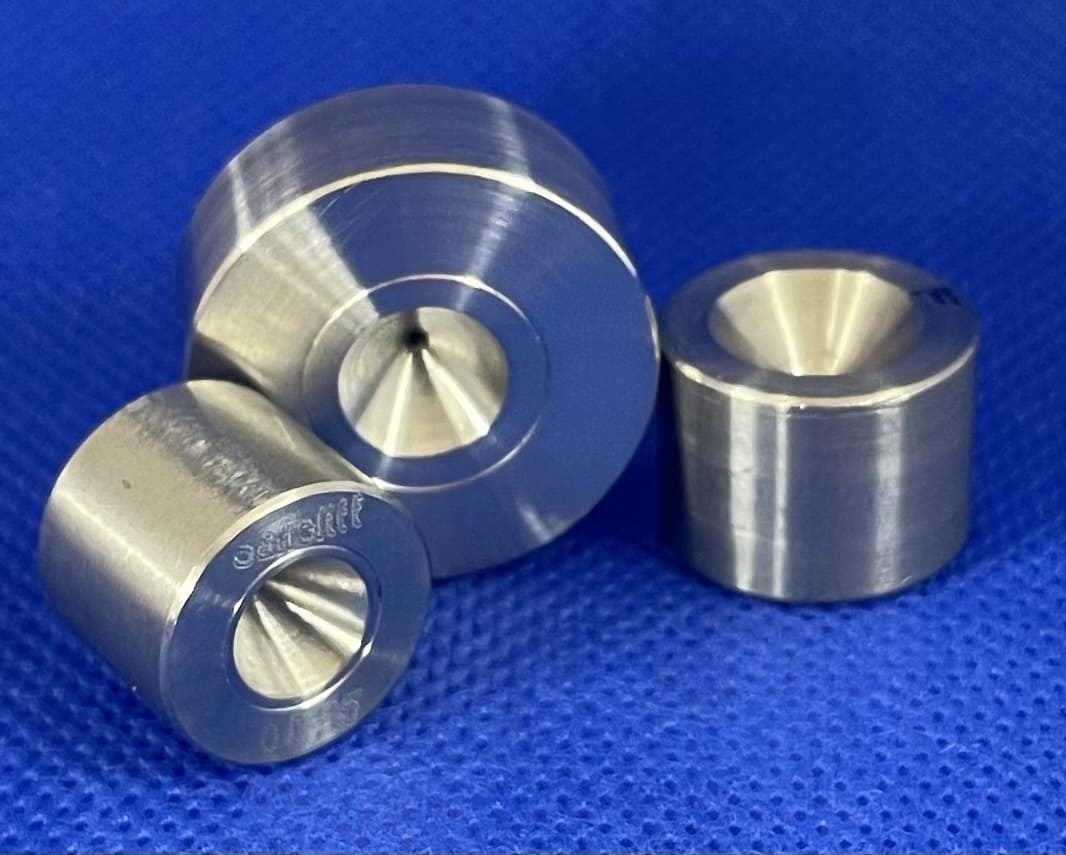

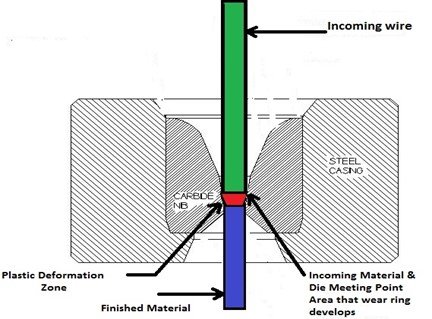

At Sancliff, we believe that quality starts with the raw materials. Our Tungsten Carbide parts undergo a rigorous quality verification process, ensuring only the best materials are used. This commitment to excellence guarantees repeatability and consistency in dimensional, geometric, and radii specifications, setting our shaped dies apart from the competition.

Endless Possibilities with Custom Shapes

Whether you need squares, hexagons, octagons, rectangles, teardrops, D shapes, stars, gears, ellipses, or ovals, we can create virtually any complex shaped drawing die profile to meet your specific needs. If you can envision it, we can bring it to life!

Expert Engineering for Optimal Performance

Our dedicated team of sales and design engineers, skilled machinists, and top-tier toolmakers work collaboratively to design and manufacture shaped drawing dies with optimal geometry. This meticulous attention to detail maximizes yield and enhances the drawing process according to the unique parameters set by each client. As a result, our customers experience increased production volume and improved wire finish and quality.

Choose Sancliff, Inc. for your custom shaped wire drawing dies and experience the difference that precision and quality can make. Contact us today to discuss your requirements and let us help you solve your most challenging shaped wire drawing applications!