Tungsten Carbide, PCD, Natural Diamond Drawing Dies, Conventional Cased Dies & Tapered TC Drawing Inserts

Wire Drawing Dies (TC, PCD, ND)

Tungsten Carbide, PCD & Natural Diamond Drawing Dies

Drawing, Stranding, Compacting, Braiding, Compressing, Extruding

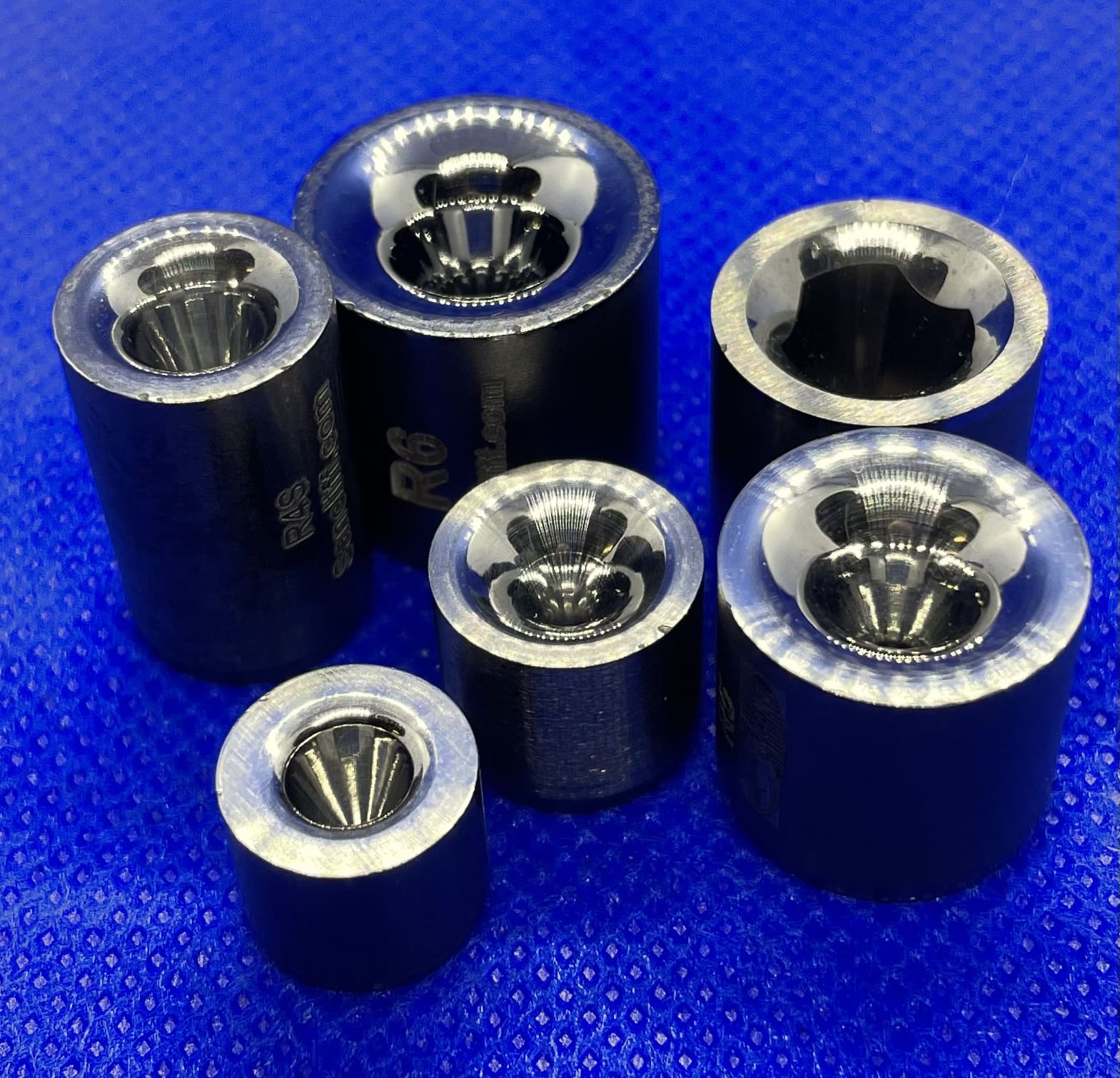

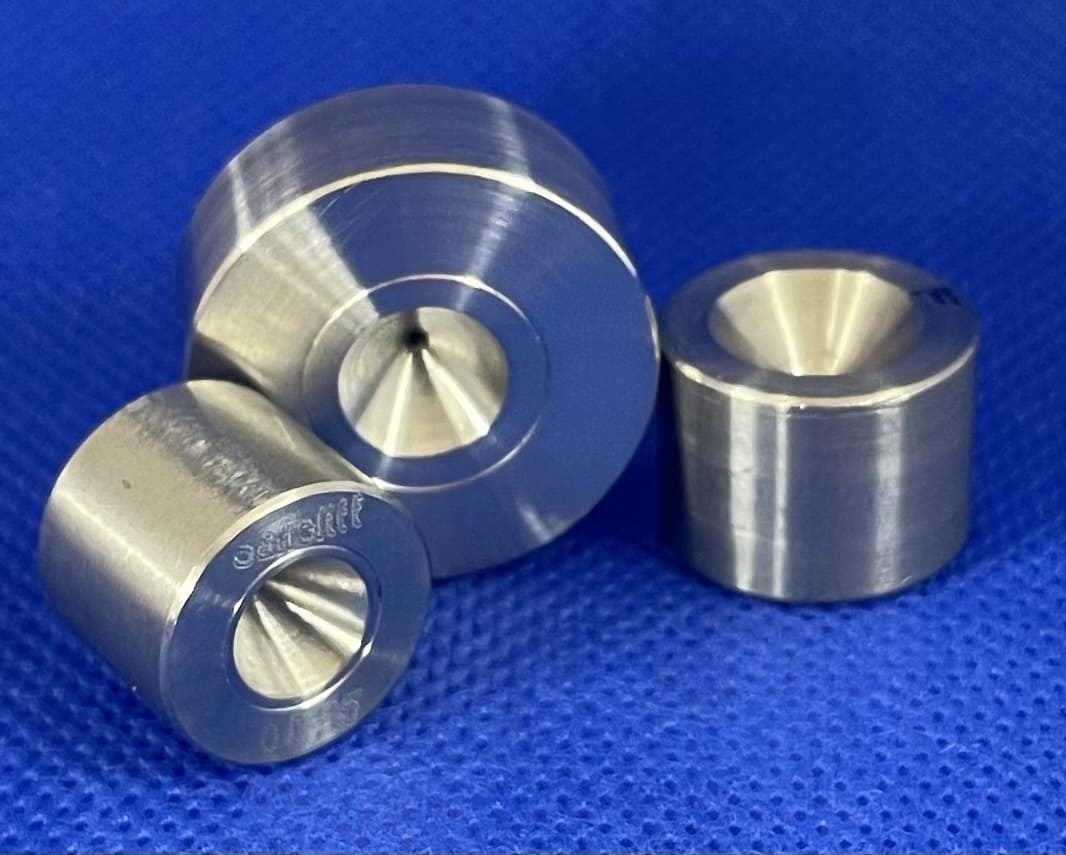

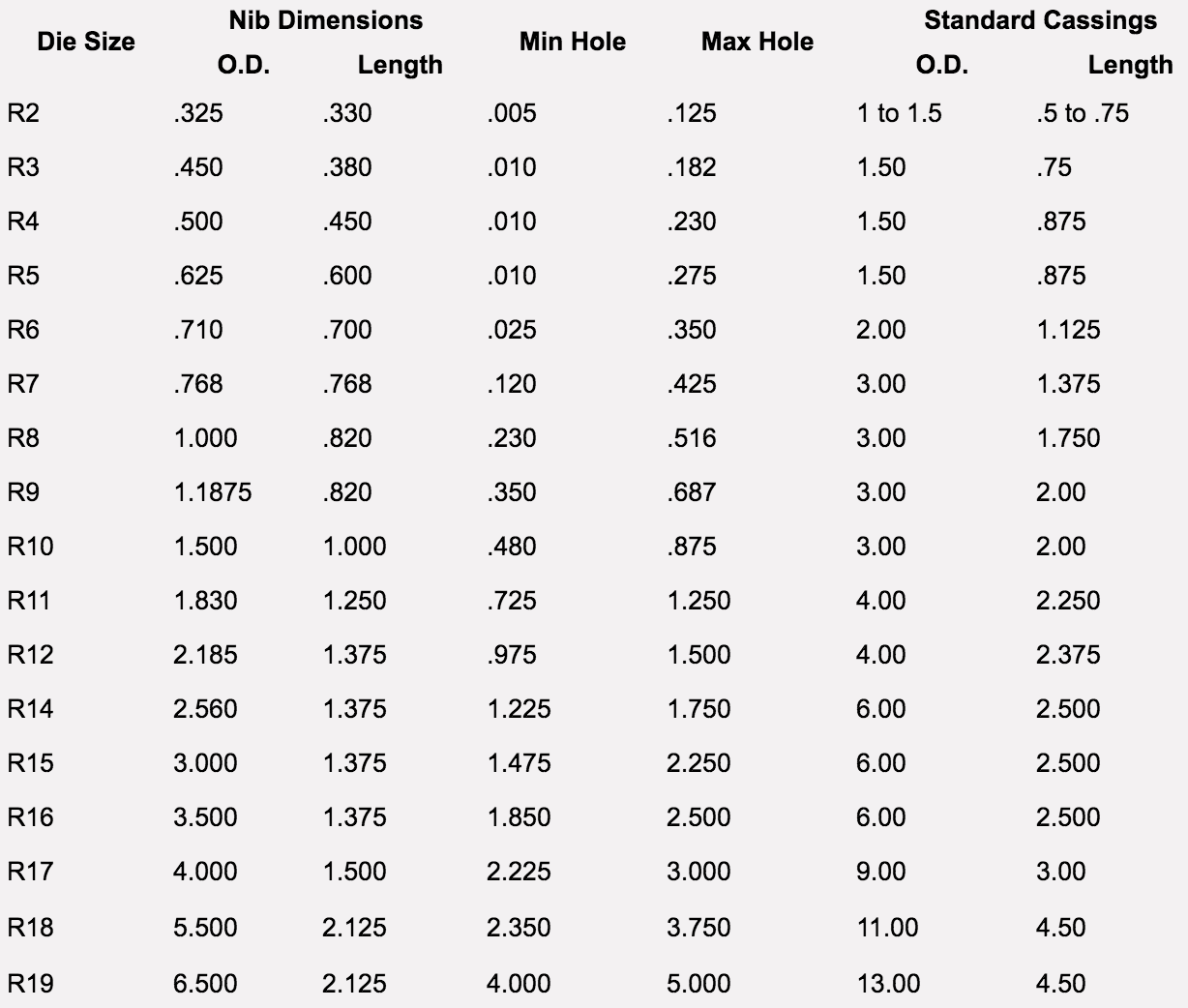

Sancliff Inc. has developed a reputation as the company to call when you need Wire Drawing Dies of all varieties. Tungsten Carbide, PCD’s, Natural Diamonds, We’re experts with all of those. Our consistently large inventory supplies of R0 – R14 & Taper Fit TR4 – T30 TC, PCD & ND blanks are always available. These large and diverse inventory levels allow Sancliff, Inc. to offer short lead times that give our customers the competitive edge.

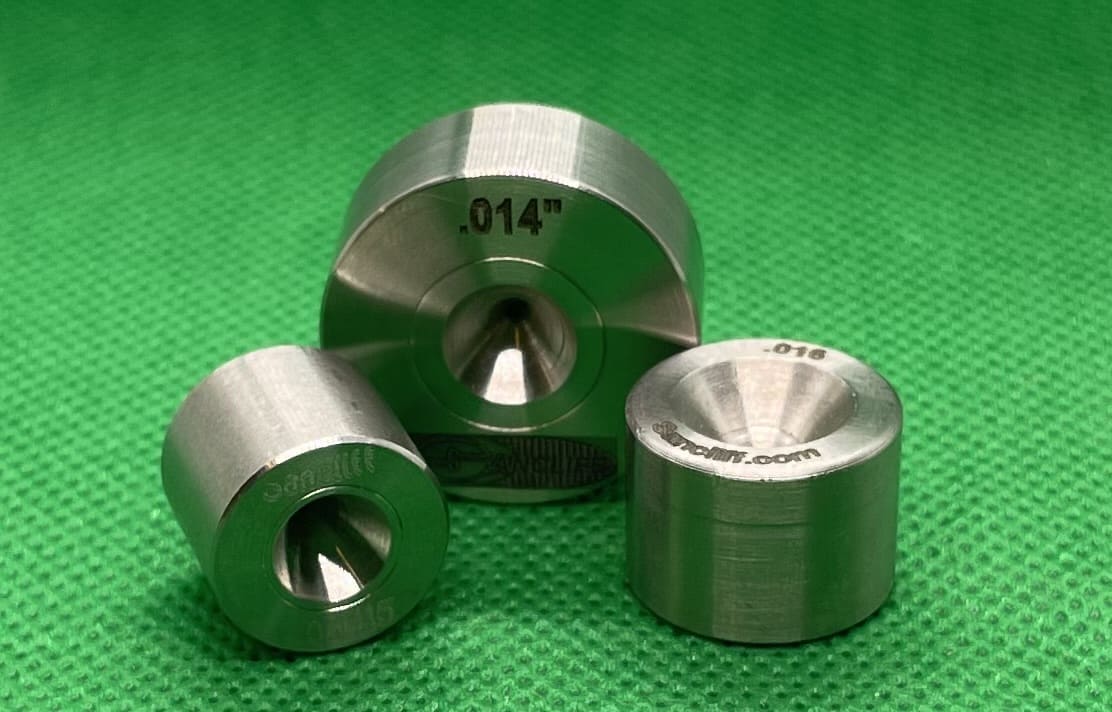

Our exacting manufacturing standards, developed by more than 70 years of experience and focus within the wire manufacturing industry, results in unsurpassed quality Tungsten carbide products manufactured to the tightest tolerances. Our Tungsten Carbide Wire Drawing Dies are available as Rough Core or Finished Dies, with I.D. sizes ranging from .002” to 5.000”, are continually recognized as the most consistent and reliable throughout the industry.

Round & Shaped Wire Drawing Dies

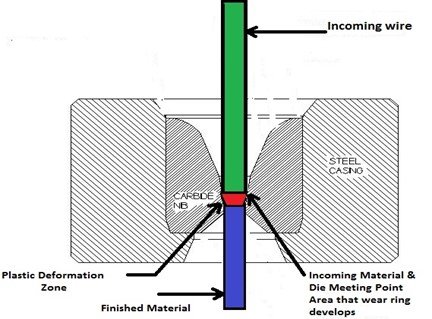

The key to successful wire drawing starts and ends with the proper wire drawing die and reduction geometry. Sancliff Inc’s wire drawing dies feature the most accurate and optimal geometry available to assure the required wire deformation is accomplished correctly. By properly drawing the wire through the tightly controlled and appropriately designed approach angle section of the die the user reduces the diameter through plastic deformation which is by definition the process of wire drawing. For good wire deformation, it is necessary to select the proper drawing die with the appropriate profile. This will ensure that the die will hold a thin film of lubricant between itself and the wire surface which is essential to minimize friction and maximize die life. Wire Drawing dies are specifically designed for either ferrous or non-ferrous materials as well as heavy or light drafting. Some materials for which the wire drawing dies were designed require areas where approach angles, bearing surfaces and back relief angles intersect to have high polish blends of these transitions. Sancliff, Inc. Wire Dies have smaller radii or sharper transitions for harder materials and larger more rounded radii for softer materials. Most Wire Die wear takes place in the approach angle by immediate abrasion at the meeting point or the area of the approach angle where incoming material and approach angle intersect. To achieve proper and efficient wire drawing it is most critical to calculate this intersecting area correctly. At first the highly polished approach angle will show only small signs of wear at the intersection point but they increase as material continues to collide at the meeting point of the two materials. This wear is characterized by the increasing development of a “wear ring” within the approach angle and at the place that the angle and incoming material intersect. Once the wear ring has developed within the approach angle the die must be withdrawn for re-sizing or re-cutting.

Sancliff Standard Wire Die Chart

For products where additional draws are needed to reach the desired finish diameter an average area of reduction per die of roughly 20% (area not diameter) is typical. Steel wire work hardens during plastic deformation and ductility is reduced while tensile strength increases. The total area of possible reduction without intermediate annealing depends solely upon the composition of the steel. It is possible through multiple subsequent or sequential draw passes through ever smaller dies to reduce cross sectional areas of the wire by up to 90%. These types of extreme areas of reduction will require intermediate annealing to restore the materials ductility.

Precision, high quality and fast turnaround are the hallmarks of Sancliff Inc. We support everything that we manufacture with a staff of knowledgeable personnel. Each team member of The Sancliff Inc. staff is always ready to assist you in planning your die needs or with any technical issues.

Tungsten Carbide Ammo Reloading Rings

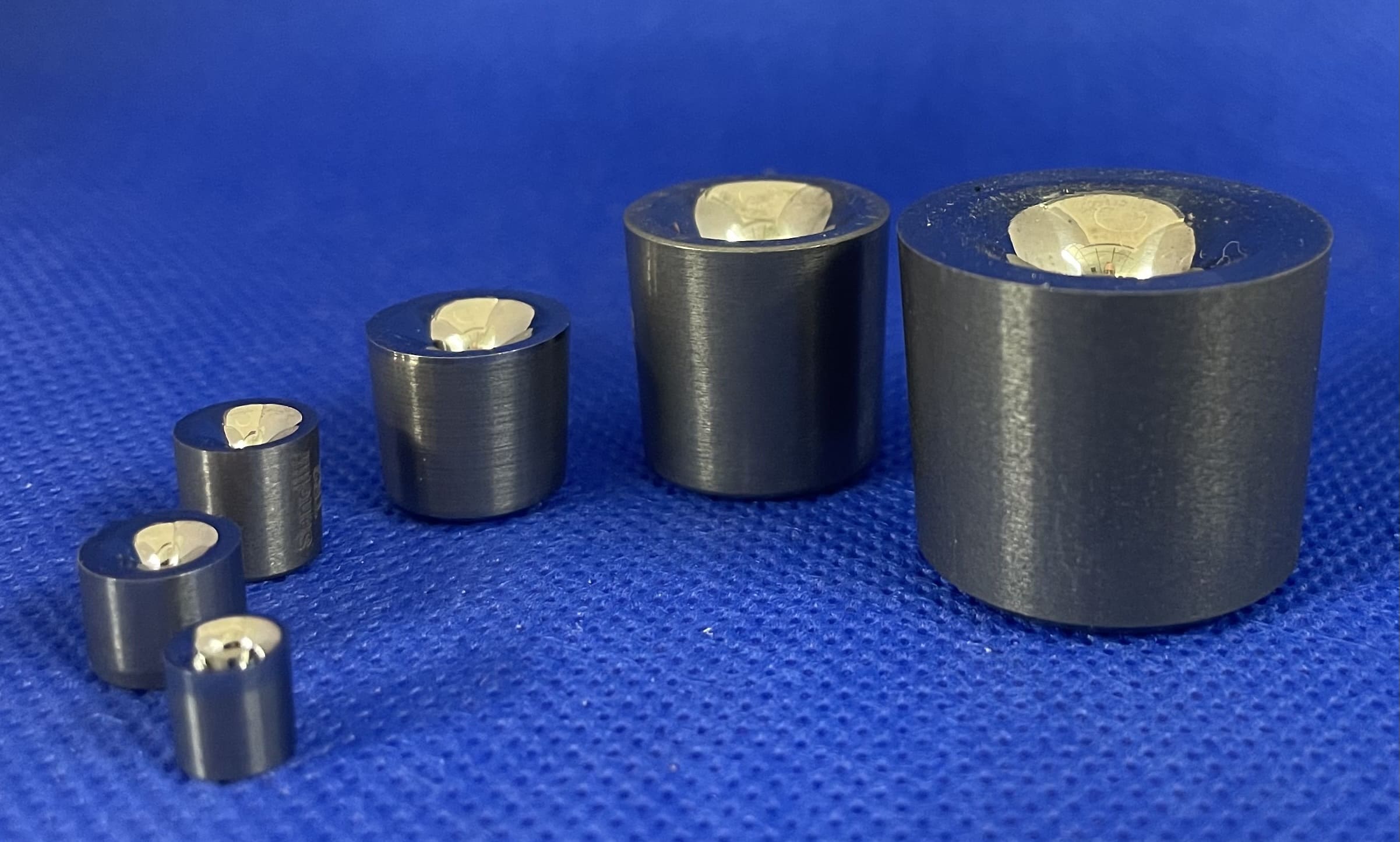

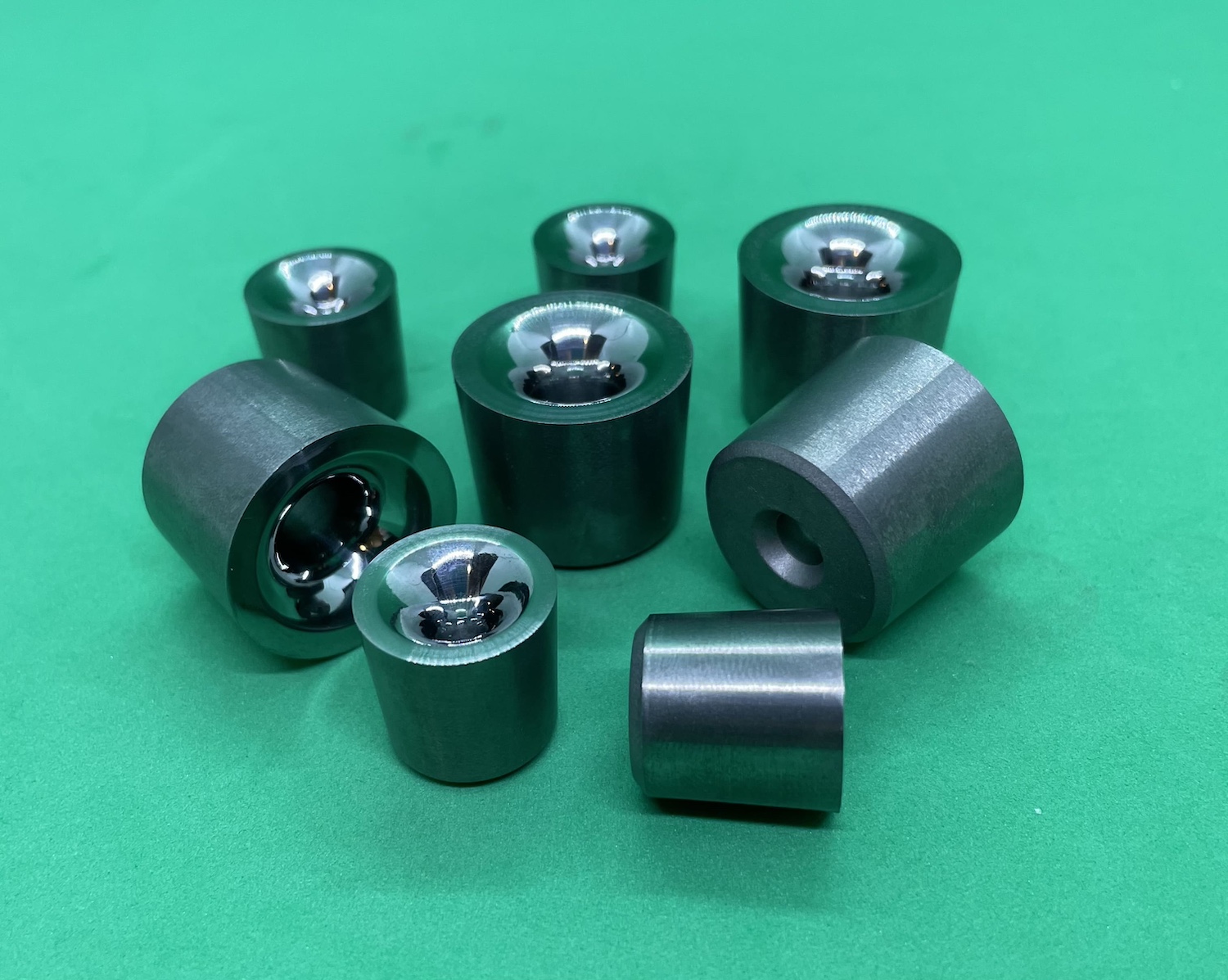

Bunching, Stranding & Compacting Dies

Extrusion Tips & Dies

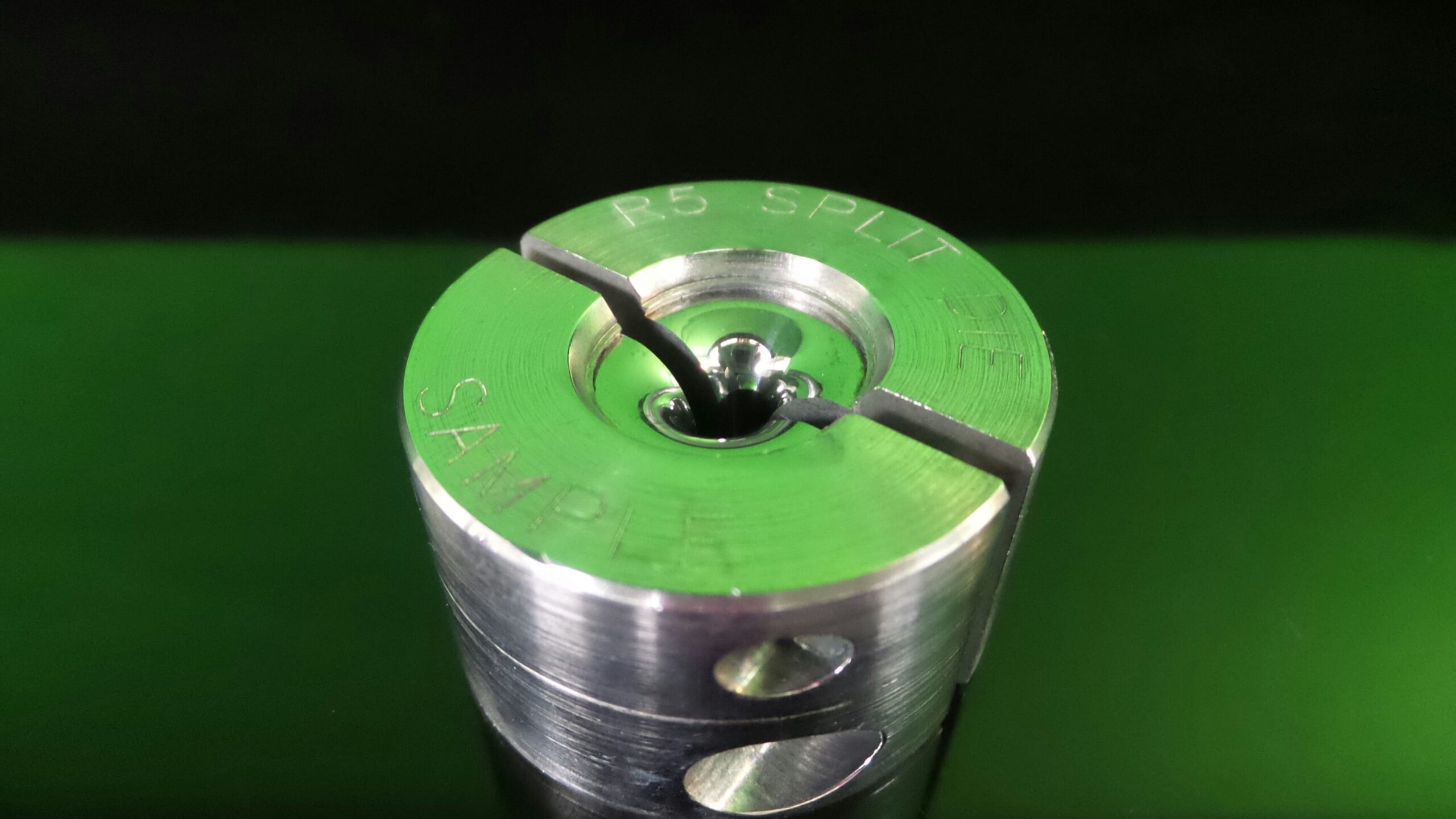

Split Drawing, Stranding & Coating Dies

Certified & Recognized By

Trusted & Quality Assured

508-795-0747

Phone Support Available 8AM – 4:30PM EDT

sales@sancliff.com

Email Support Available 6AM – 4:30PM EDT

Visit us

97 Temple Street, Worcester, MA 01604