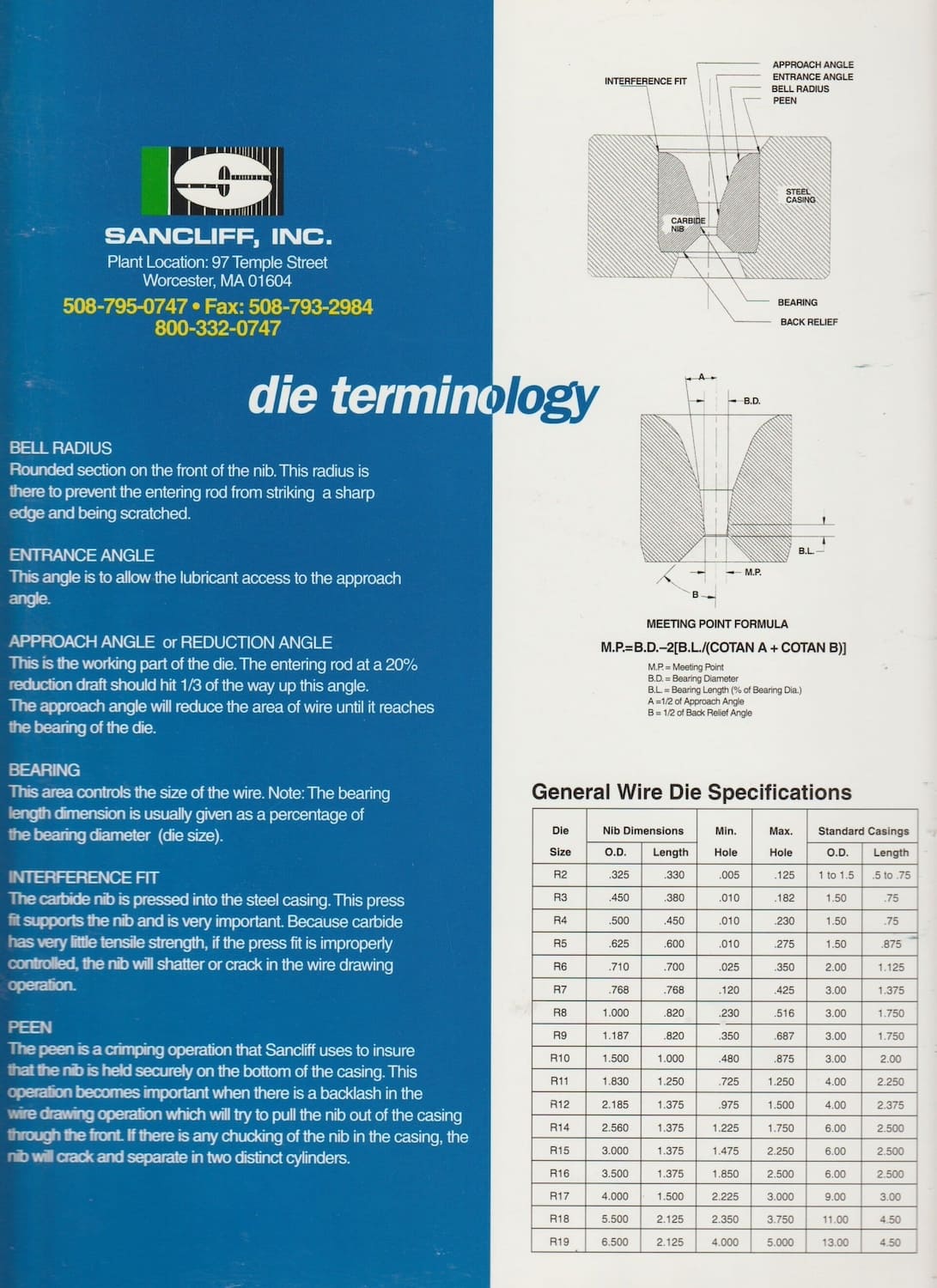

Bell Radius – The rounded section on the front of the nib. This radius is there to prevent the entering rod from striking a sharp edge and being scratched.

Approach or Reduction Angle – The working part of a die. The approach angle will reduce the area of a wire until it reaches the bearing of a particular die. (Example: An entering rod approaching at a 20% Reduction Draft should hit 1/3 of the way up this angle)

Entrance Angle – The angle that allows the lubricant access to approach angle

Interference Fit – The carbide nib is pressed into the steel casing. The interference fit supports the nib and is very important because since carbide has low tensile strength, if a press fit is improperly controlled, the nib with either shatter or crack the in the wire drawing operation.

Bearing – The area that controls the size of the wire passing through. (NOTE: The bearing length is normally given as a percentage of the bearing diameter)

Peen – The crimping operation that we use to ensure that the nib is held securely on the bottom of the casing. The operation becomes vital when there is backlash in the wire drawing process, which will try to pull the nib out of the casing through the front. If there is any chucking of the nib within the casing, the nib will crack and separate into two distinct cylinders.

Die Terminology

Speed is Key

On time deliveries and fast responses are our words to live by. You’re going to be satisfied by the time your done with your first order.

Expert Team

Your project will be handled by experts every time. We make sure you have the most experienced professionals working for you.

Locked In Support

You’ll find the support you need to ensure that things runs smoothly. Every time. We’re here to help you with any questions.