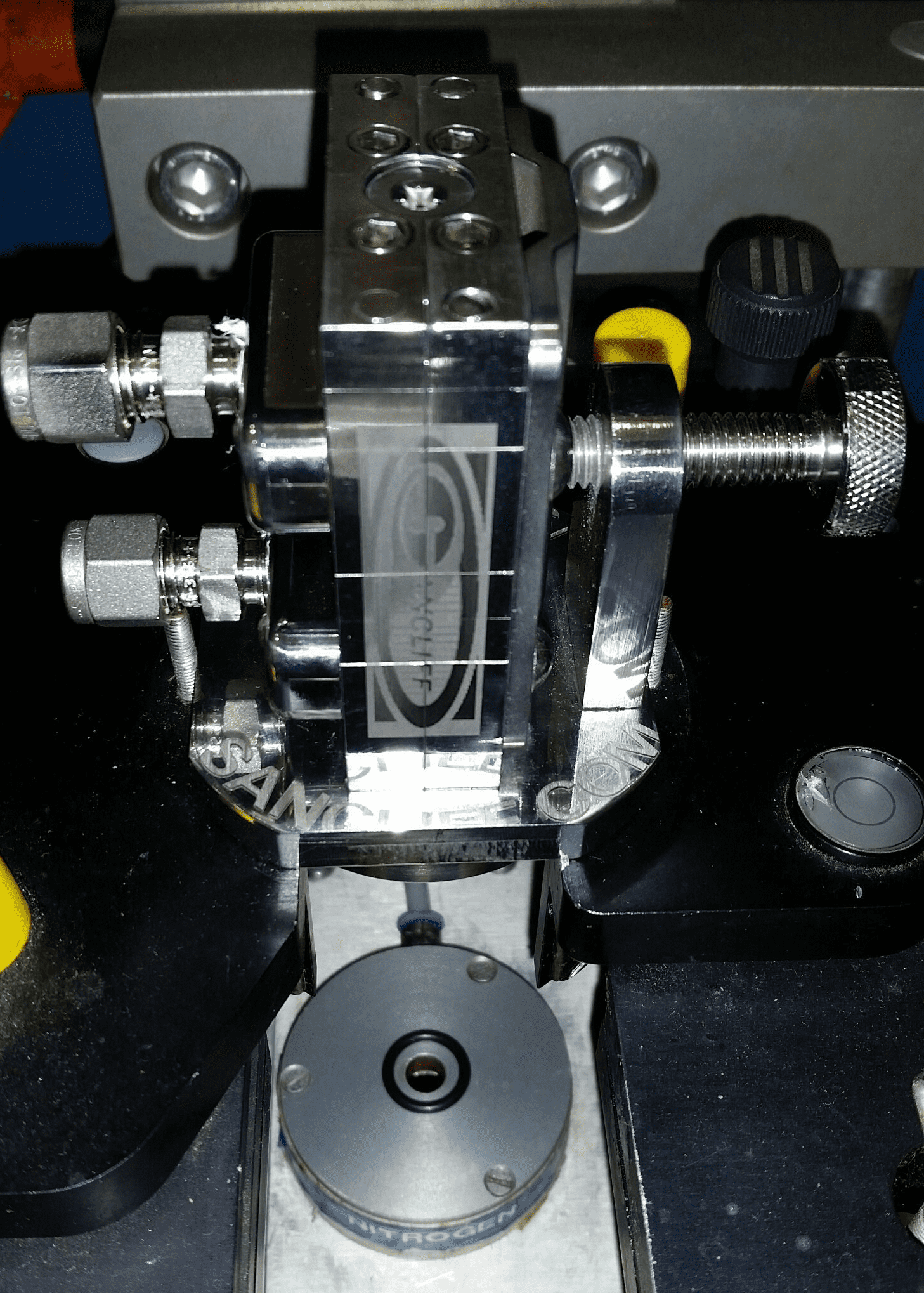

Sancliff, Inc’s exclusive designs of Optical Fiber Coating Heads & dies available in both split and solid designs will move your coating application projects to the next level. Sancliff has been manufacturing Tungsten Carbide Coating Dies for the Optical Fiber industry since 1980. Sancliff has extensive experience manufacturing O/F Ribbon Shaped Dies. From 6F – 48F and beyond in both continuous and splittable ribbon shapes we can assist immediately with your most challenging applications. In addition to our exclusive die designs we are precision manufacturers of hundreds of custom coating die designs for our vast customer base around the world. Chances are that if you have any branded or custom coater in your facility, Sancliff has produced dies for this coater type and we can help you with your requirements today.

Optical Fiber Coating Dies And Applicators

Optical Fiber Coating Dies And Applicator

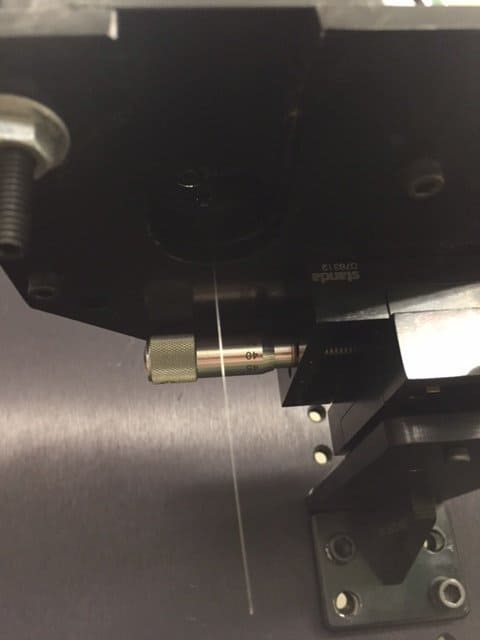

Sancliff, Inc. Fiber Optic Coating Dies and Head Assemblies control the thickness and concentricity, as well as apply a protective layer of specified coating over the bare or coated fiber during the drawing or re-coating process. This protects it from the environment that the material will be exposed to. Applied acrylate or polyamide coatings on the bare glass or previously coated fiber also provide protection from mechanical damages such as cable or fiber bending, and/or kinking. This prevents the ingress of moisture into the microscopic flaws on even the most pure glass preforms.

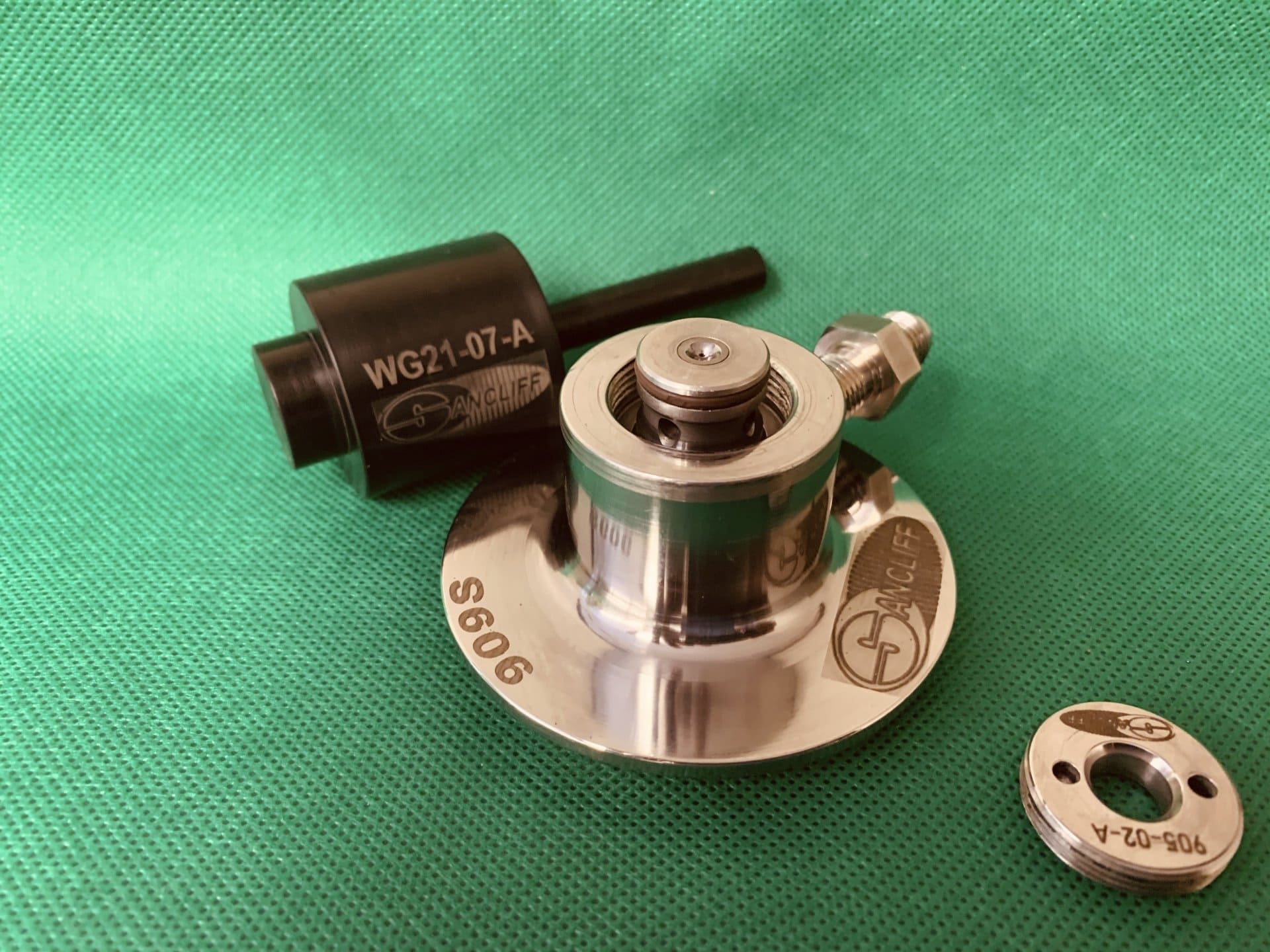

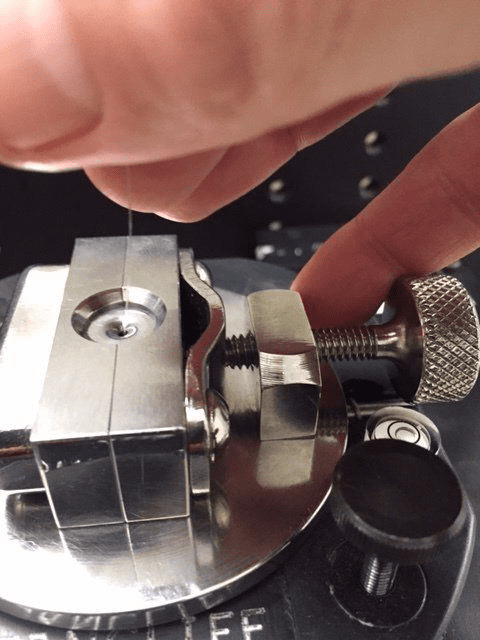

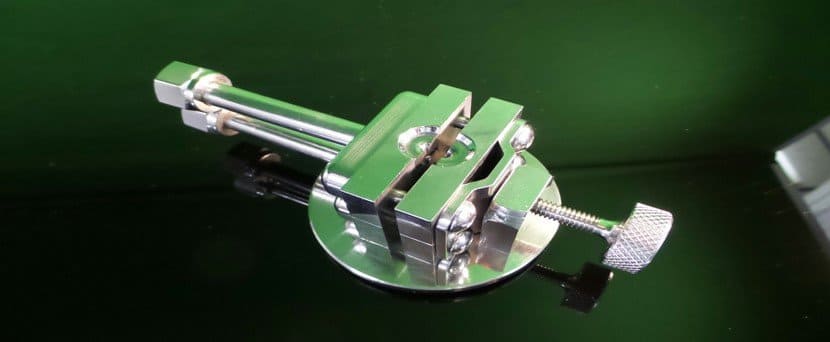

Split Optical Fiber Coating Die Applicators

A Split Coating applicator, also commonly referred to as a “Head” is a 2 piece split ID hole die that employs a stationary half of a coating chamber with a retractable side. When closed they form a pressure chamber to apply the coating to the chosen substrate. The coating chamber is open when the substrate is being aligned on the draw tower, and closed when the substrate is aligned in the coating chamber. The coating fluid is then fed into the chamber and the draw continues. Split Coaters are size specific to each mission, and therefore are most practical if the user is making short runs, or if jamming or substrate upsets occur often. The Split Coater is easy to maintain, clean and restart if jams or other draw problems occur.

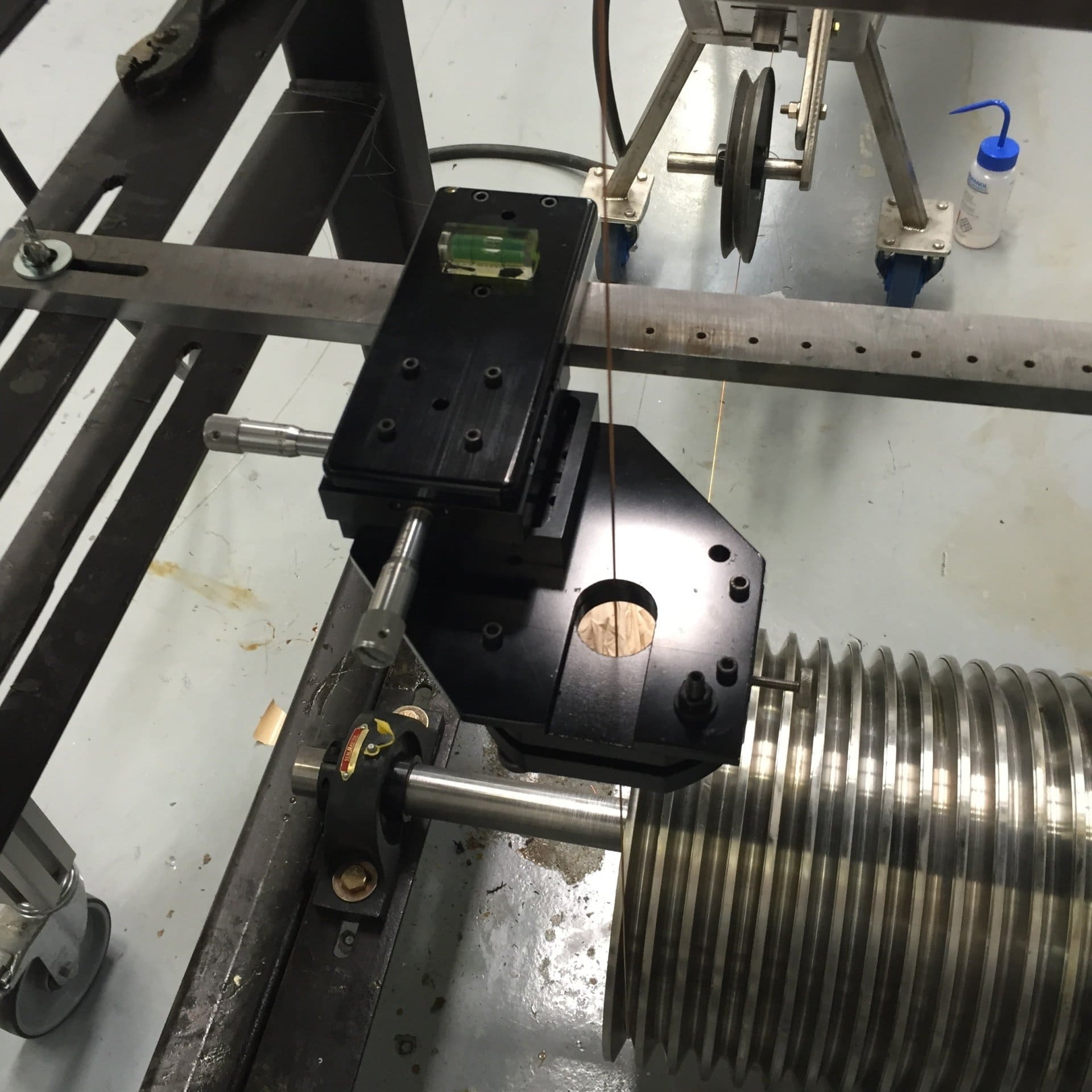

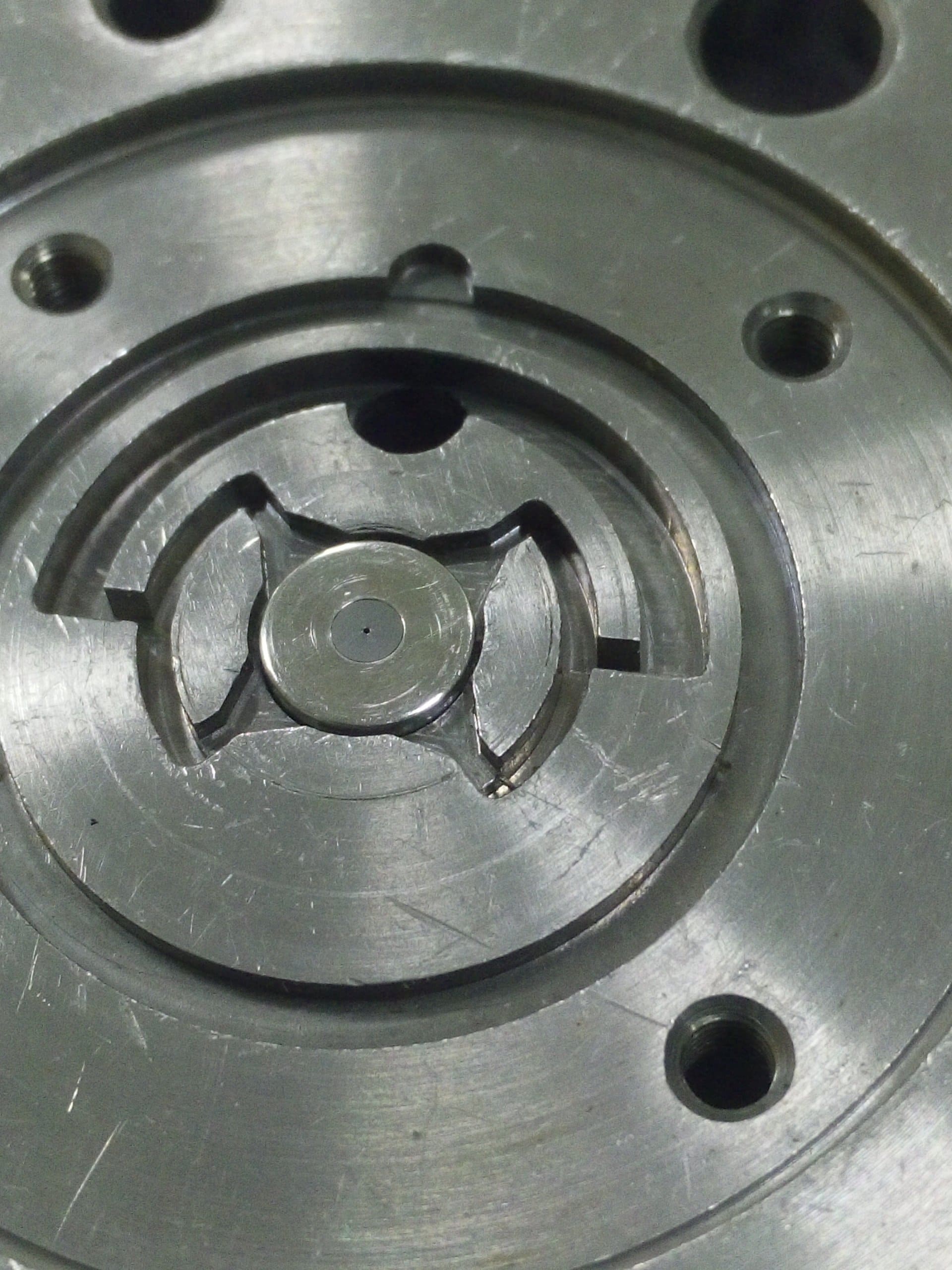

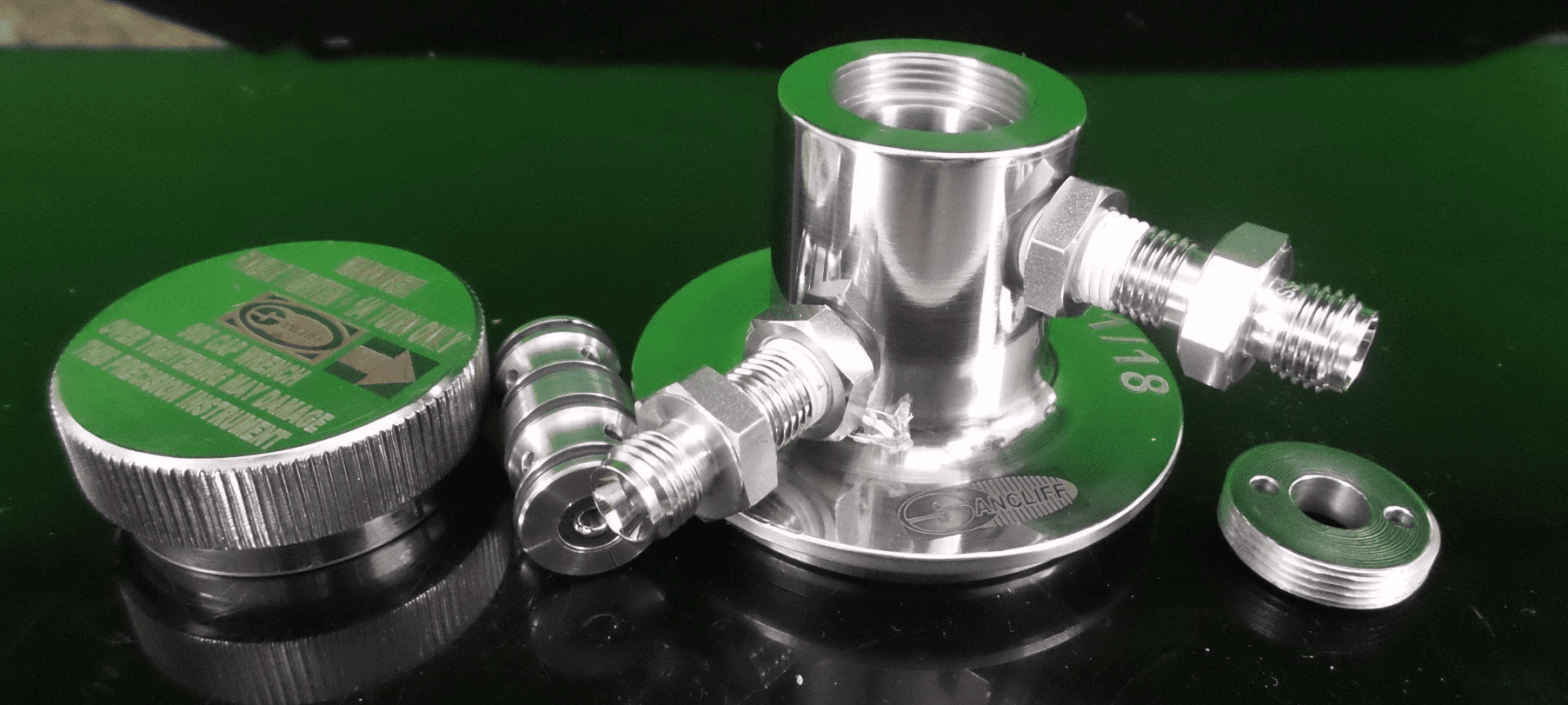

Solid Optical Fiber Coating Die Applicators

Solid Coating applicators consist of a body containing 2 sealed dies to form a coating chamber. The “Solid” refers to the ID hole of the die insert. The dies are replaceable and interchangeable which allows the user to match Dies with substrates of different diameters and coatings with varying characteristics. Since the entrance and exit dies can be changed at will, these coaters are more versatile. They are preferred for longer runs and for runs where the substrates are less likely to jam, break or otherwise stop the draw prematurely.

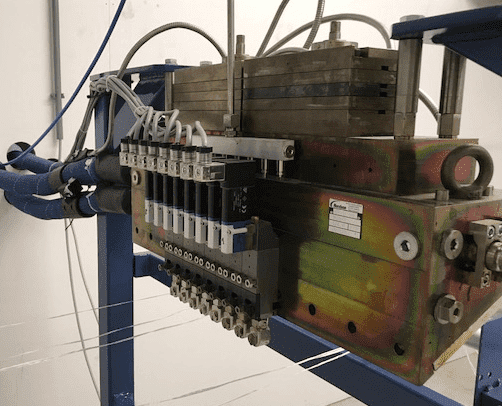

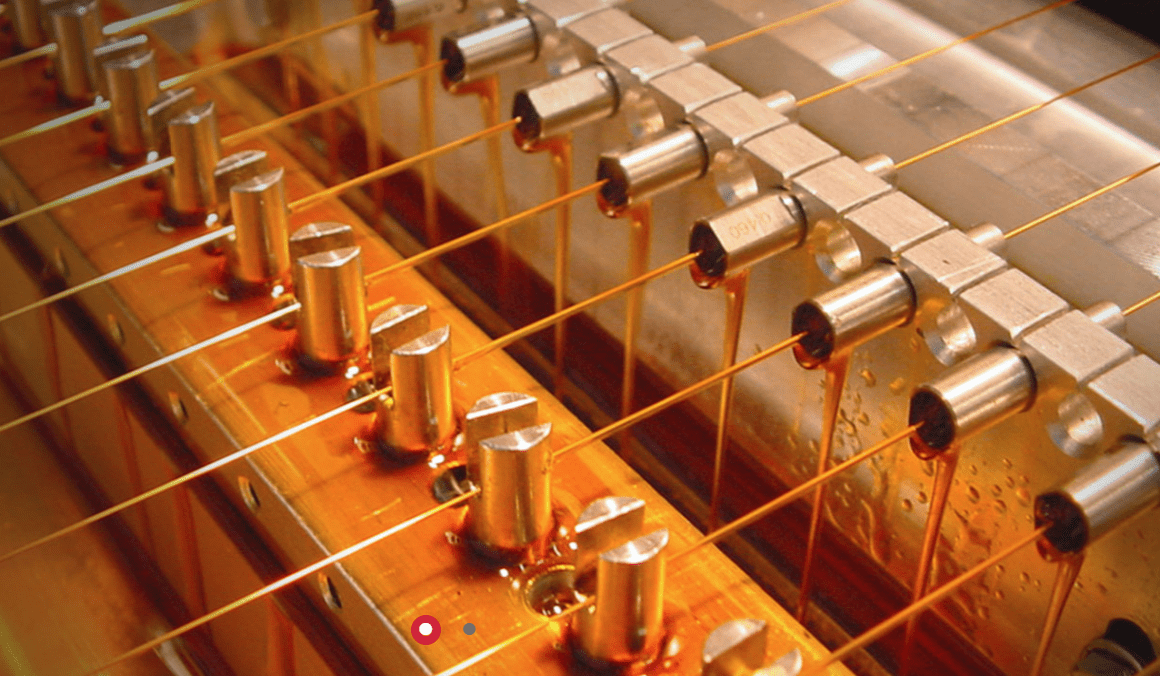

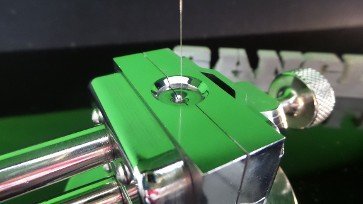

Split Optical Fiber, Wet on Wet Coating Die Applicators

Split Wet on Wet Coating Heads are hybrid coaters that give the user the ability to apply 2 coatings in-line without sacrificing speed, concentricity or size. Naturally the coatings must be compatible with each other and will cure with a single device such as a UV Fusion Lamp. Sancliff’s Fiber Optic Cladding Dies, Coating Dies, Fiber Optic Coating Head Assemblies and Fiber Optic Pressurized Coating Systems are engineered to deliver controlled supplies of diverse chemical composition and varied viscosity coating to our Fiber Optic Coating Head and Die Assemblies.

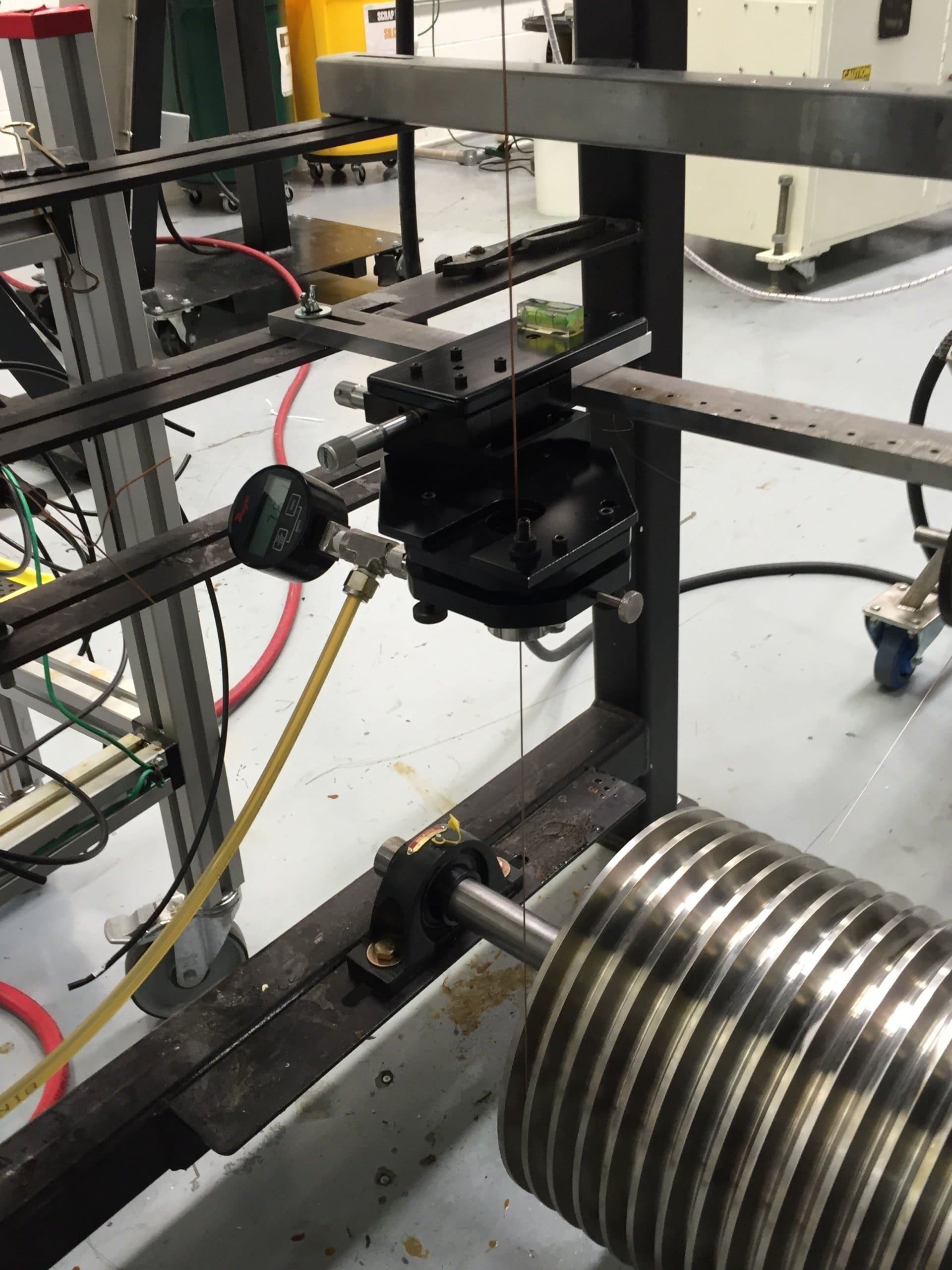

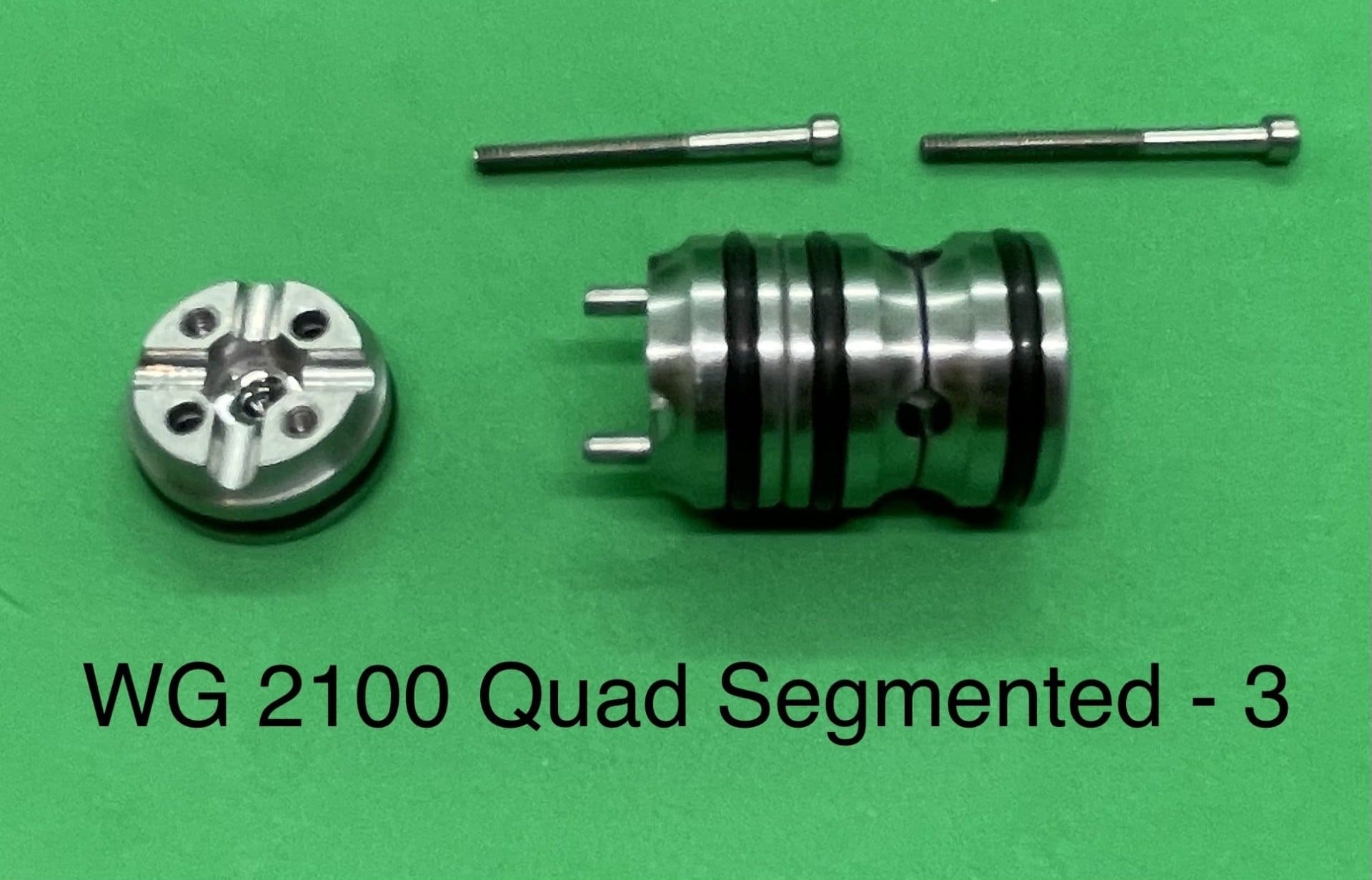

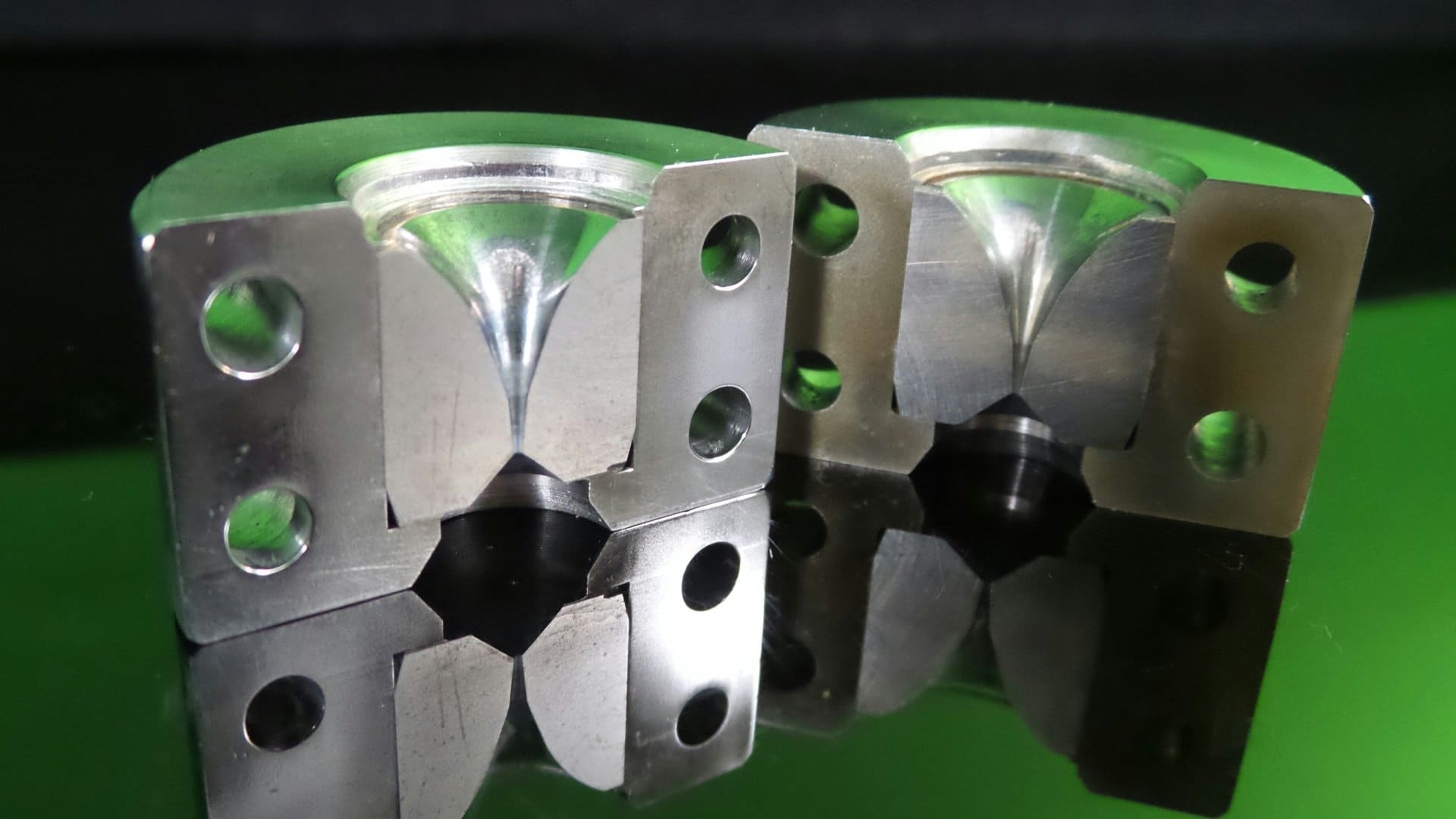

Solid Optical Fiber, Wet on Wet Coating Die Applicators

Solid Optical Fiber, Wet on Wet Coating heads have developed a great deal in recent years. Sancliff has perfected a very versatile Quad die design that allows the end user greater flexibility to mix and match sizes for differing incoming and finish parameters as well as deal with a dreaded fiber jam.. As with any Sancliff optical fiber WOW die this die can be used as a single stage coating applicator at any time.

Cladding and Coating devices are available in split, solid, wet on wet, twin and multi configurations for conventional round and/or specialty shaped fibers and substrates. Low and even pressurization of the Sancliff, Inc. Fiber Optic Coating Head chambers assists in the control of the size and application of concentric coating material upon the specified substrate, as well as preventing meniscus collapse as the fiber enters the coating chamber. From ultra-thin to heavy Claddings and Coatings, Polyimides or Acrylates, high speed or low speed, there is a Sancliff Coating System and Coating Head to meet your needs.

Certified & Recognized By

Trusted & Quality Assured

508-795-0747

Phone Support Available 8AM – 4:30PM EDT

sales@sancliff.com

Email Support Available 6AM – 4:30PM EDT

Visit us

97 Temple Street, Worcester, MA 01604