Accuracy Starts with Quality

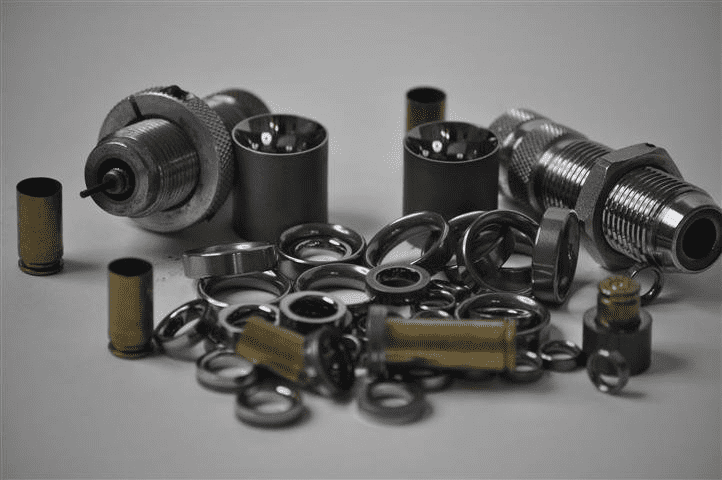

At Sancliff, we understand that the foundation of superior ammunition is rooted in precision and consistency. Our ammo resizing dies and reloading dies are crafted from the highest quality Tungsten Carbide, a material renowned for its durability and resilience. Each die is engineered with meticulous attention to detail, utilizing the finest transitional blends and surface finishes available in the industry. This commitment to quality ensures that every round you produce meets the highest standards of accuracy and reliability.

Innovative Design Features

One of the key aspects of our resizing dies is the design of the carbide reloading rings. The mouth of the carbide ring features a large radius, which is crucial for ensuring that cases align effortlessly on progressive presses. This design minimizes the risk of case misalignment during the reloading process, allowing for smoother operation and reducing wear on both the dies and your reloading equipment. This thoughtful engineering not only enhances efficiency but also contributes to the overall quality of the ammunition produced.

Our sizing dies are available in a comprehensive range of calibers, from the precision of .17 HMR to the robust power of .50 caliber. This extensive selection allows you to find the perfect die for virtually any reloading application, whether you’re crafting small varmint loads or heavy-duty rounds for large game.

Custom Solutions for Unique Needs

At Sancliff, we recognize that every reloader has unique requirements. That’s why we offer both our tried-and-true in-house designs and the option for customization. If you have specific dimensions or features in mind, our experienced team can work with you to create a die that perfectly fits your reloading setup. Whether you need a specialized taper, unique sizing parameters, or a specific finish, we are committed to delivering a solution that meets your exact needs.

Enhanced Performance with Polished Surfaces

The exceptional performance of our dies is further enhanced by our highly polished carbide surfaces. These polished finishes not only provide superior resistance to wear and corrosion but also significantly reduce sizing force. This means less strain on your reloading press and improved overall efficiency during the reloading process. Additionally, our carbide primer buttons are designed to work seamlessly with our resizing dies, ensuring a smooth and reliable reloading experience from start to finish.

Trust Sancliff for Your Reloading Components

When it comes to reloading, precision and reliability are paramount. Look no further than Sancliff for your reloading components. Our dedication to quality, innovative designs, and customer-focused solutions makes us the preferred choice for reloaders who demand the best. Trust Sancliff to help you achieve the accuracy and performance you expect from your ammunition.